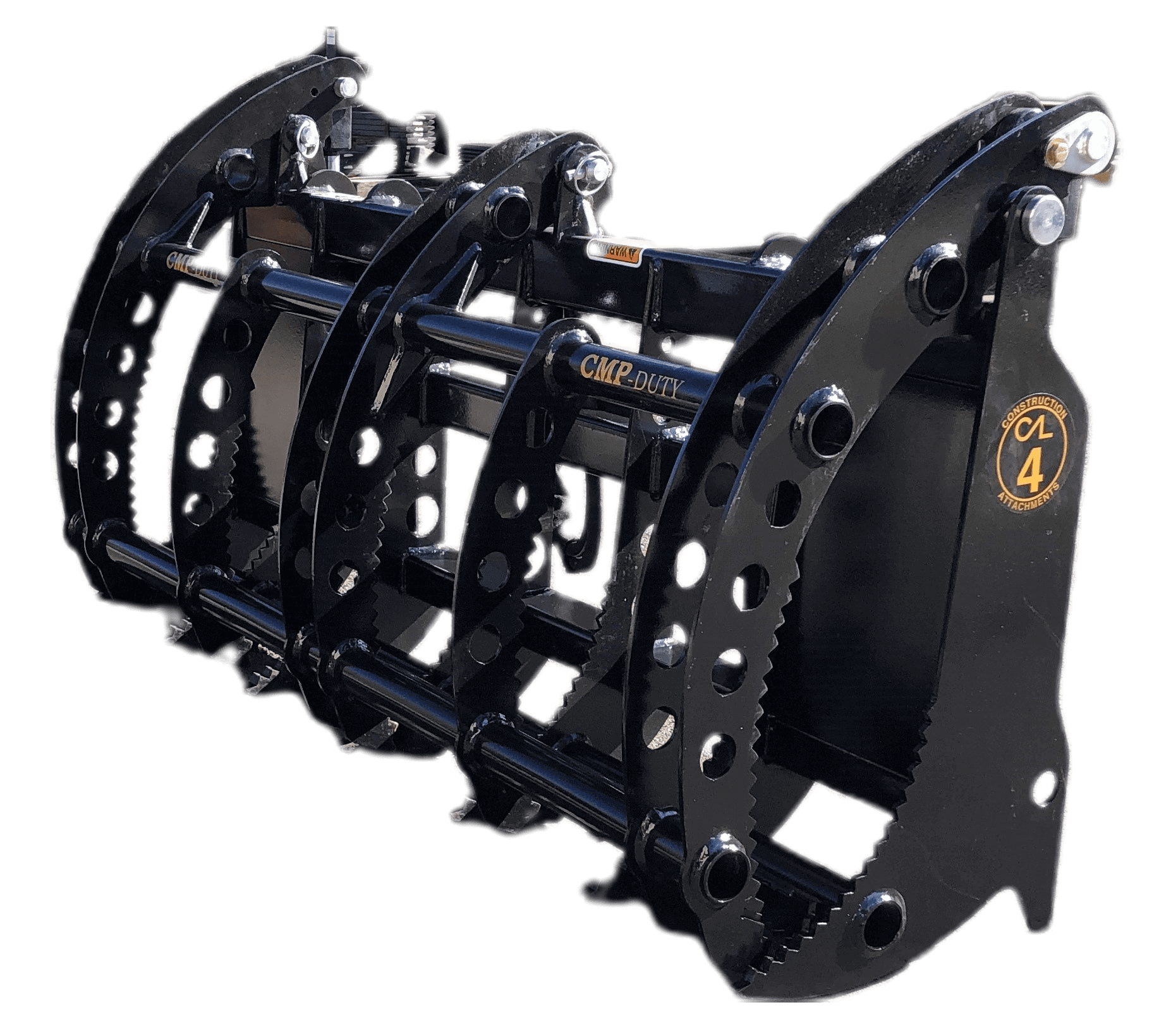

Compact Root Rake Grapple – Tractor Loader Attachment

Compact Root Rake Attachment designed for tractor loaders. Designed to handle a wide range of jobs for excavating roots, brush, rocks, and other debris to loosen and smooth the ground while leaving behind the soil. Also used for transport of brush and debris. Grapple lids may also be used for back-dragging. Ideal for construction, agriculture, landscaping, industrial, and many other applications.

Product Features:

- For tractor loaders up to 50 to 75 horsepower

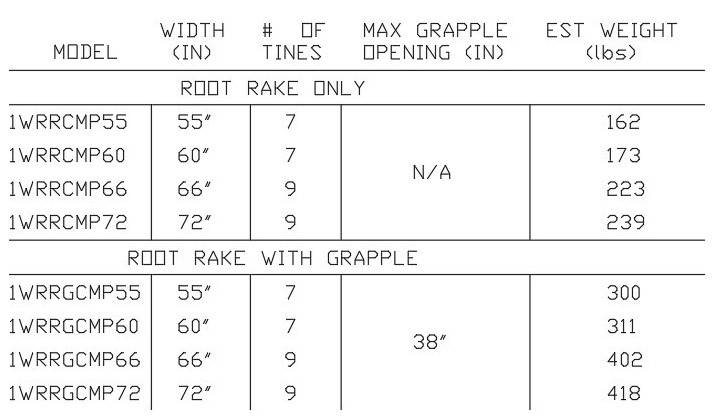

- Available in 55”, 60”, 66”, & 72”

- ¾” Rake Tine Thickness

- Universal Skid Steer Quick Attach

- 1″ Rake Tine Thickness

- 2.25″ Cylinder Bore

- Hoses and couplers included

Designed for:

- Excavating roots, brush, rocks and other debris

- Loosen and smooth ground while leaving soil behind

- Transport brush and debris

- Grapple lid can be used for back-dragging

SKU:

AFE281

Categories: All Products, CAL Duty Ratings, Duty Ratings, Grapple Attachments

Shipping & Delivery

Related products

Bolt-On Reversible Cutting Edge

Bolt-On Reversible Cutting Edges are designed to add protection and longevity to your original front edge on Construction Attachments general purpose and multi-purpose buckets. Made from high strength 1080 High Carbon Steel. Will fit Construction Attachment buckets with pre-drilled weld in edges based on bucket model.

Hydraulic Breakers – Mid & Large Excavators

Construction Attachments Hydraulic Breaker for Mid-Large Excavators are designed for construction and demolition of concrete structures, rocks, asphalt, and more.

Designed for aiding in construction and demolition of concrete structures, rocks, asphalt, etc.

- Constructed of high strength steel to provide structural durability

- Silence kit ensures noise protection, prevents dust and debris from entering breaker housing

- Cushion Damper provides protection to the host machine

- Auto Stop (Anti Blank Fire) System ensures less problem of the components and longer life of the breaker

- Specify make and model of host machine when placing order

- Weights may vary based on selected hitch styles

- Use of unsuitable hydraulic couplers or hoses can cause damage to internal components of breaker.

- Hydraulic lines < 60 gpm – use 1.0 inch lines AND > 60 gpm – use 1.25 inch lines.

- Dry firing hydraulic breaker can result in damage to internal components of breaker and host machine.

- Chisel paste must be used with hydraulic breakers, using high temperature grease as a substitution for chisel paste will cause damage to components of breaker.

- Consult with appropriately trained hydraulic specialists prior to placing breaker into service.

- Read operators manual before use.

- Check hydraulic flow and pressure before use.

- Instruct owner/operator on proper use of hydraulic breaker before delivery of machine or product.

Pirahna Forestry Mulcher

Xtreme Duty Dual Bale Spears

Xtreme Duty Pallet Forks

Duty Ratings, CAL Duty Ratings, Pallet Fork Attachments, Skid Steer Loaders, Tractor Loaders, Xtreme Duty, All Products

Xtreme Duty Trailer Relocator Attachment

Xtreme Duty Walk-Through Regular and Heavy Lift Pallet Forks

Duty Ratings, CAL Duty Ratings, Pallet Fork Attachments, Skid Steer Loaders, Xtreme Duty, All Products